Sebakeng se matla sa motsoakomoqomotlhahiso, thepa ea mechine ea li-liner e phetha karolo ea bohlokoa ho netefatsa hore li tšoarella le ho phela nako e telele. Sengoliloeng sena se shebisisa lintlha tse rarahaneng tsa hore na tlhahlobo e hlokolosi le tlhahlobo ea lisebelisoa tsena tsa mochini li kenya letsoho joang ho thehenglisilindaratse emang tekong ya nako.

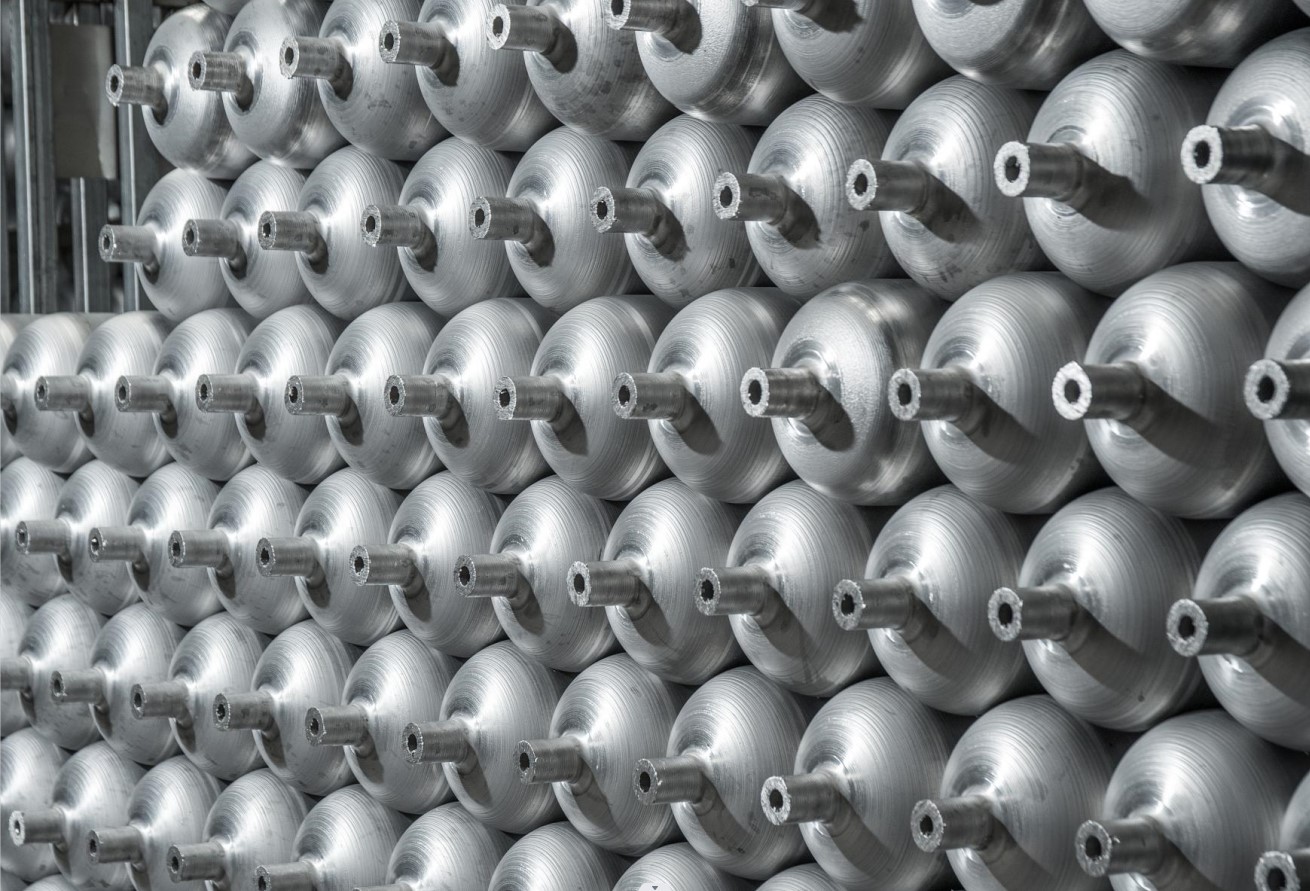

Ho Utloisisa Karolo ea Li-Liners: Li-Liners li theha sebopeho sa mantlha sa motsoakolisilindara, ho fana ka tšehetso ea bohlokoa le mamello. Thepa ea mochini, ho kenyeletsoa matla a ho tiea, ho thatafala, le bots'epehi ba sebopeho ka kakaretso, ke lintlha tsa bohlokoa ho lekanyeng ho tiea ha li-liner tsena.

Teko ea Matla a Matla: Leeto le qala ka tlhahlobo e felletseng ea matla a liner's tensile. Teko ena e lekola bokhoni ba mochini oa liner ho mamella matla le likhatello tsa kantle, ho netefatsa hore e ka mamella maemo a thata ao e ka tobanang le ona lits'ebetsong tse fapaneng joalo ka ho tima mollo, ts'ebetso ea pholoso le ts'ebeliso ea indasteri.

Teko ea boima: Ho qoela ka botebo tekong ea ho thatafala ho senola hore na e lekanya khanyetso ea liner ho deformation le ho apara. Thepa ena e bohlokoa ho netefatsa hore liner e ka mamella litlhoko tsa ts'ebeliso ea eona e reriloeng, e fana ka motheo bakeng samoqomo's ka kakaretso tšepahala.

Tekanyetso ea Thepa ea Mechini: Ka holim'a matla le boima bo tsitsitseng, tlhahlobo e akaretsang ea thepa ea mochini oa liner e etsahala. Mohato ona o lekola bokhoni ba liner ho boloka botsitso ba sebopeho tlas'a khatello, ho netefatsa hore e lula e le karolo e tiileng le e ka tšeptjoang ka har'a motsoako.moqomo.

Tiisetso ea Boleng ka Teko e Matla: Ts'ebetso ea taolo ea boleng e hloka ho nepahala le ho tsitsa. Ka ho lekola mekhoa ea mochini oa li-liner, bahlahisi ba ka tseba ho kheloha kapa bofokoli bofe kapa bofe bo ka senyang boleng ba sebopeho sa liner.moqomo. Teko ena e thata e tiisa hore ntho e 'ngoe le e' ngoe e kopanemoqomoho siea moeli oa tlhahiso ho kopana le ho feta litekanyetso tsa indasteri.

Litlamorao ho Basebelisi ba Qetello: Bakeng sa basebelisi ba ho qetela ts'ebetsong ea ho tima mollo, ts'ebetsong ea pholoso, le likarolo tse ling tsa bohlokoa, ho utloisisa tlhahlobo e hlokolosi ea thepa ea mochini ho fana ka kholiseho ho ts'epahalo ea motsoako.moqomos ba itšetlehile ka. Tsenamoqomos ha se lihlahisoa feela; ke litharollo tse entsoeng ka boenjiniere tse etselitsoeng ho mamella mathata a ts'ebeliso ea tsona.

Qetello: Ha re ntse re manolla mathata a ho hlahloba thepa ea mochini ea li-liner tse kopanengmoqomotlhahiso, hoa totobala hore mohato o mong le o mong ts'ebetsong ea tlhahlobo o kenya letsoho ho ts'epahala le ho tšoarella ha sehlahisoa sa ho qetela. Boitlamo ba bokhabane ba ho utloisisa le ho ntlafatsa thepa ena bo tiisa hore ho kopanemoqomos ha se likaroloana feela empa ke bahlokomeli ba tiileng ts'ebetsong ea bohlokoa, e hahiloeng ho tšoarella.

Nako ea poso: Dec-04-2023